Pros and cons among different lithium batteries

Not only smartphones and laptops, but even bicycles and cars, all kinds of tools we use in our daily life are powered by electricity. Improving battery performance has important implications for improving the ease of use of these devices. Among them, lithium batteries have attracted the attention of the industry in recent years.

Here we talking about the classification and application of different lithium batteries

1. What is a lithium battery

Strictly speaking, lithium batteries are divided into two types: lithium metal batteries and lithium ion batteries. This is defined according to the form in which lithium exists.

Lithium metal batteries use metal lithium as the electrode, while lithium ion batteries exist in the electrode in the form of ions. Lithium metal batteries generate electricity through the corrosion or oxidation of metal lithium, and they are useless when they are used up and cannot be charged, so they are also called primary batteries.

Lithium-ion batteries are a type of rechargeable batteries that use graphite or other carbon materials as the negative electrode and lithium-containing compounds as the positive electrode, so they are also called lithium secondary batteries. It is a type of battery that uses lithium metal or lithium alloy as the positive/negative electrode material and uses a non-aqueous electrolyte solution.

2. The classification and characteristics of lithium-ion batteries

According to the different metal materials used in the positive electrode, lithium-ion batteries are divided into several types. The metal material used in the positive electrode of the original lithium-ion battery is cobalt. However, the output of cobalt is almost as small as lithium, and it is also a rare metal with high manufacturing costs. Therefore, cheap and environmentally friendly materials such as metals such as manganese, nickel, and iron have been used.

Lithium-ion batteries are classified according to the materials they use. Let's take a look at the characteristics of each type.

Cobalt lithium-ion battery

Use Lithium cobaltate for the positive electrode. Lithium cobaltate is relatively easy to synthesize and easy to use, so the earliest mass production of lithium-ion batteries is lithium-cobaltate batteries. But because cobalt is a rare metal and expensive, it is hardly used in auto parts.

Manganese lithium-ion battery

Use lithium manganate for the positive electrode. The advantage is that the voltage can be similar to that of cobalt lithium-ion batteries, and the manufacturing cost is cheap. The disadvantage is that manganese may melt into the electrolyte during charging and discharging, shortening the life of the battery.

Iron phosphate lithium-ion battery

Use lithium iron phosphate for the positive electrode. The advantage of the iron phosphate lithium-ion battery is that it is difficult to damage the internal heating structure, has high safety, and uses iron as the raw material, so the manufacturing cost is lower than that of the manganese lithium-ion battery. But the voltage is lower than other Lithium-ion batteries.

Ternary lithium-ion battery

The ternary lithium-ion battery is a battery made of three materials, cobalt, nickel, and manganese, in order to reduce the amount of cobalt used. At present, most of the ternary lithium-ion batteries have a high proportion of nickel. Although the voltage is slightly lower than that of cobalt-based and manganese-based, it can reduce manufacturing costs. However, despite this, the synthesis and preparation of each material is difficult, and the stability is low, and there are still problems to be solved as practical materials.

3. Lithium battery pollution

According to the composition of the lithium battery, lithium iron phosphate in the positive electrode material does not contain heavy metals and basically has no pollution, while lithium manganese, ternary lithium, and lithium cobalt have heavy metal elements (manganese, cobalt, nickel) and have heavy metal pollution. Compared with lead-acid and nickel-chromium batteries, lithium iron phosphate battery’s pollution is very small, but for the environment, chemicals are still harmful.

The electrolyte is composed of organic solvents and lithium salts. Organic solvents generally include PC, EC, DEC, DMC, DME, etc., among which DMC is slightly toxic, and others are non-toxic. The lithium salt is lithium hexafluorophosphate (the most used, and there are other lithium salts), it will be hydrolyzed into HF when it meets water, which is poisonous. The shell, diaphragm adhesive will cause white pollution, and the rest of the battery materials can be recycled without pollution.

We don't need to be careful about environmental pollution when we use batteries normally, but we need to pay attention to recycling when used batteries are scrapped to prevent the leakage of battery materials from causing pollution and burden to the environment.

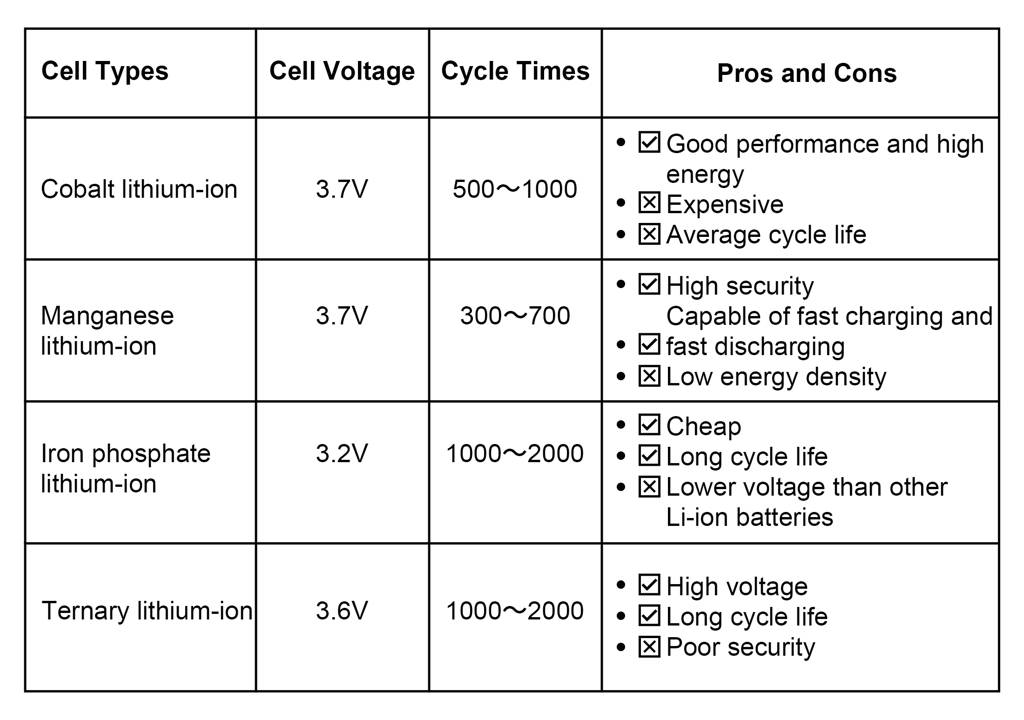

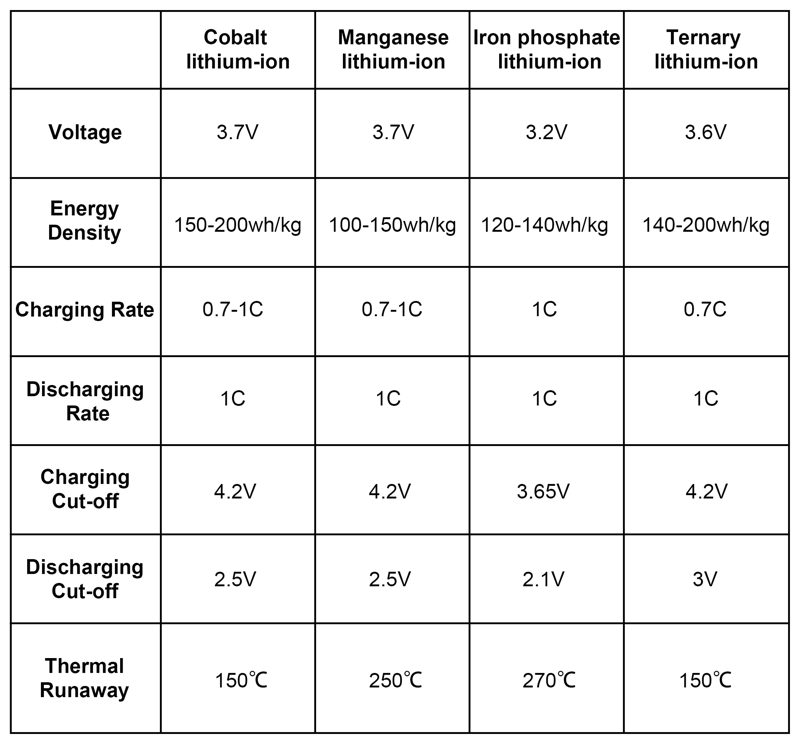

4. Working performance comparison(cell)

5. Lithium battery application

Lithium cobalt : Because of its excellent energy density, it has a smaller weight and volume under the same energy and is used as a small energy battery, becoming a popular choice for mobile phones, notebook computers and digital cameras.

Lithium manganate: Although the overall performance is average, industrial applications require a battery system with good load capacity, long life, and safety. It’s commonly used in power tools, medical equipment, electric transmission systems, etc.

Lithium iron phosphate: It has good safety and long life, moderate energy density and strong discharge capacity, and is used as power lithium battery and energy storage battery.

Ternary lithium: It has high energy density and low temperature resistance, the biggest application is in new energy vehicles, such as Tesla's ternary lithium power battery.

Above we talked about the five aspects of lithium batteries, each of which has its own unique advantages and has a very wide range of applications in individual fields.

Of course, now and in the future, different lithium batteries will appear and be applied in more fields, providing continuous development for the new energy industry.