Closed-Loop vs. Open-Loop Communication

Closed-Loop vs. Open-Loop Communication

I. Open-Loop Communication

I. Open-Loop Communication

Title

Title

Title

Title

Title

II. Closed-Loop Communication

II. Closed-Loop Communication

Title

Title

Title

Title

Title

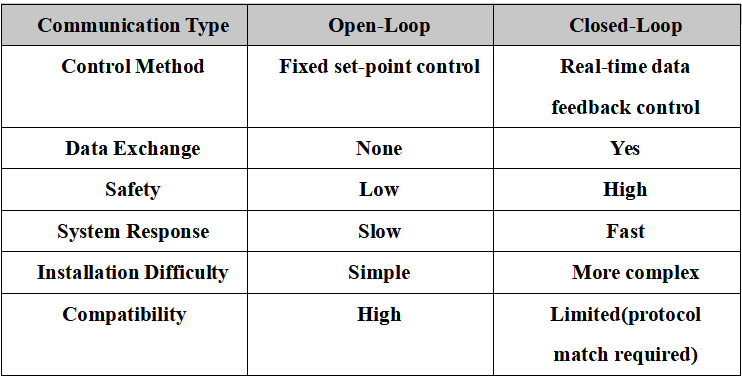

III. Summary Comparison

Ⅳ. Recommended Application Scenarios

Ⅳ. Recommended Application Scenarios

Title

Related Products